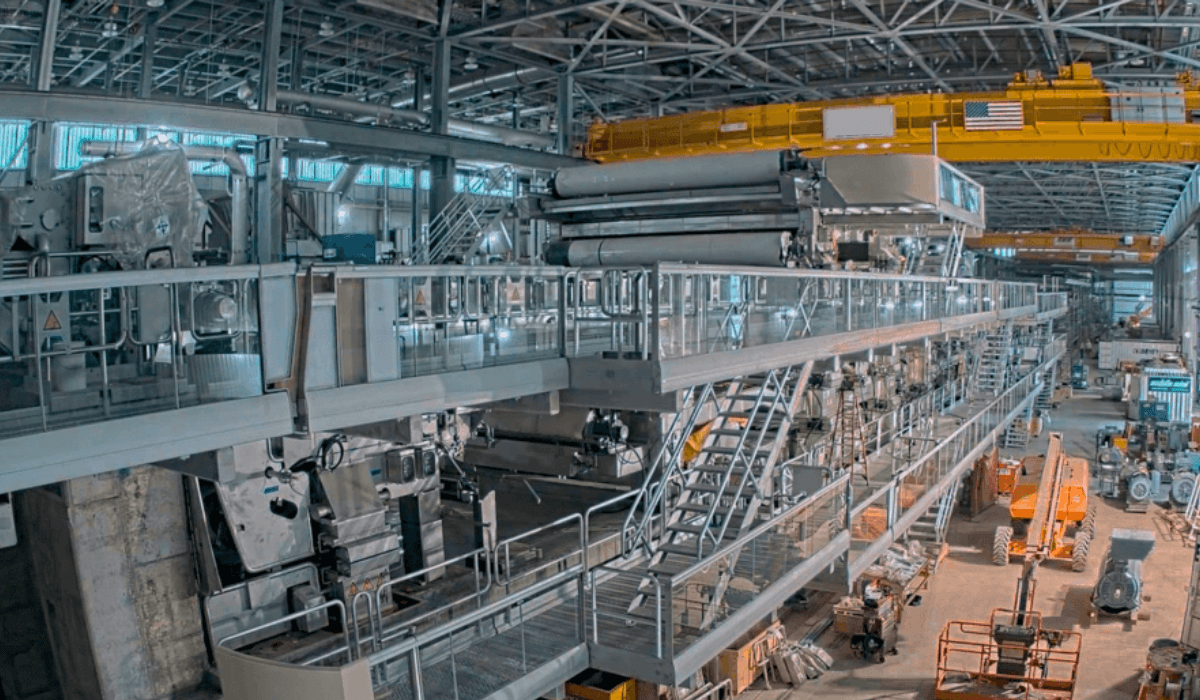

Graphic Packaging International (GPI) notified us that they needed assistance in getting a project back on schedule, which turned into a much larger project problem-solve.

ParFab with over 15,000 welds completed (12,000 Stainless steel, 3,000 Carbon steel) and installed 700 devices, control valves, flow meters and valves.

Client Background

Graphic Packaging International is a leading provider of paper-based packaging solutions including folding cartons, cups, foodservice packaging and other commercial products.

Project Details

- ParFab Services Job 5850 Graphic Packaging International (GPI) and Job 5866 Weiland System Walkdown Kalamazoo, MI

- Project Start Date July 28, 2021

- Project Completion Date February 03, 2022, for Piping job

- Project Completion Date March 31, 2022, for Systems Walkdown

Background

In July 2021, ParFab received a phone call that GPI's project was behind schedule and needed assistance getting things back on track. Our team showed up with only a small crew prepared to do small bore piping, off the header to the equipment, around 8,000 feet.

With the other contractors falling behind, we were given more scope when it was all said and done.

- ParFab Companies installed 33,290 feet of small-bore piping (2’’ and below) and 22,206 feet of large bore piping, up to 72’’ all Stainless Steel.

- ParFab made 3,376 large bore welds and 12,558 small bore welds

- ParFab installed over 700 devices valves, control valves and flow meters

Our systems walkdown team reviewed isometrics and P&ID’s verifying that everything was installed correctly and to specification, marking up discrepancies and reporting back to GPI.

Manpower

ParFab started with a crew of 10 welders, 10 pipefitters and 10 boilermakers. 30 days into the job, we had grown to 100 crew members per shift.

By the end of October, we had reached a total of 360 crew members, where the systems walkdown began with just one guy and had grown to 6 total men.

Learn how ParFab can help with fabrication services, field services and heat exchanger services.