Shutdowns play a crucial role in the maintenance of plants. The planning and execution of shutdowns differ significantly from routine or weekly planning processes.

Frequently asked questions:

- What is shutdown planning?

- How long does a shutdown last?

- How often are shutdowns required?

- What tasks are completed during a shutdown?

- What does a shutdown process look like?

- How do I schedule a plant shutdown or emergency turnaround?

What is shutdown planning?

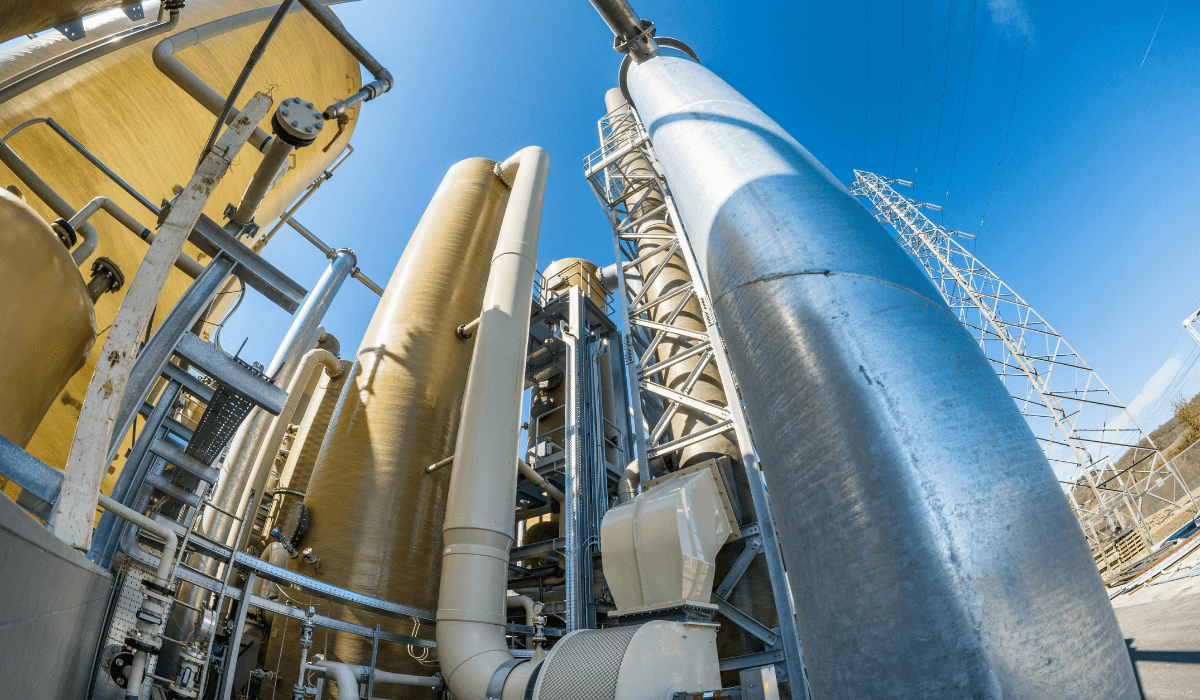

Shutdown planning (also referred to as shutdowns, shutdown maintenance, turnarounds or outages) refers to the process of strategically scheduling and coordinating the temporary shutdown of a facility or a specific section of a facility for maintenance, repairs, upgrades, or other necessary activities. Shutdowns are typically planned in industrial settings such as manufacturing plants, refineries, chemical plants, power plants, and other large facilities like a metal fabrication shop, where continuous operation is crucial but periodic maintenance is also required to ensure safety, efficiency, and compliance with regulations.

How long does a shutdown last?

The duration of a shutdown can vary significantly depending on various factors such as the scope of work, the size and complexity of the facility, the extent of maintenance or repairs needed, and the availability of resources.

Some shutdowns may last only a few hours for minor maintenance tasks or equipment inspections, while others can extend for several days or even weeks for more extensive overhauls, upgrades, or major repairs. In industries like oil refineries or chemical plants, shutdowns can sometimes last for several weeks or even months for comprehensive maintenance activities known as turnaround maintenance.

Ultimately, the duration of a shutdown is determined by the specific requirements of the maintenance or repair work being undertaken and the timeline established during the planning phase.

How often are shutdowns required?

The frequency of shutdowns varies depending on several factors, including the type of facility, the equipment used, operational demands, regulatory requirements, and the overall maintenance strategy employed by the organization.

-

Routine Maintenance Shutdowns: Many facilities schedule regular, planned shutdowns for routine maintenance activities, such as specialty welding. For example, scheduled shutdowns are essential for storage tanks.These may occur on a weekly, monthly, quarterly, or annual basis, depending on the maintenance schedule developed by the maintenance team. Routine shutdowns are often scheduled to coincide with periods of lower production demand or during scheduled maintenance windows.

-

Turnaround Maintenance Shutdowns: In industries such as oil refining, petrochemicals, and certain manufacturing sectors like digital transformation in manufacturing and Manufacturing Execution Systems (MES), comprehensive maintenance activities known as turnaround services or shutdowns are conducted periodically. These shutdowns typically occur every few years and involve extensive maintenance, repairs, equipment inspections, and upgrades. Turnaround maintenance shutdowns are essential for ensuring the long-term reliability, safety, and efficiency of the facility.

-

Unplanned Shutdowns: In addition to planned shutdowns, facilities may experience unplanned shutdowns due to equipment failures, emergencies, safety concerns, or other unforeseen circumstances. These unplanned shutdowns can disrupt operations and may require immediate attention to restore production.

The frequency of shutdowns is often determined by balancing the need for maintenance with the need to maintain continuous production. Effective maintenance planning and scheduling aim to minimize unplanned downtime while ensuring that necessary maintenance activities are completed to prevent equipment failures, ensure safety, and optimize operational performance.

What tasks are completed during a shutdown?

During a shutdown, various tasks are typically completed to ensure that maintenance, repairs, inspections, and other necessary activities are carried out efficiently and effectively. The specific tasks undertaken during a shutdown can vary depending on the type of facility, equipment, maintenance requirements, and the scope of work involved. However, common tasks during a shutdown may include:

-

Equipment Inspections

-

Preventive Maintenance

-

Repairs and Replacements

-

Upgrades and Modifications

-

Cleaning and Overhaul

-

Testing and Commissioning

-

Safety Inspections and Compliance

What does a shutdown process look like?

The shutdown process can be organized into 5 turnaround phases, from initial planning to the completion of maintenance activities and the resumption of operations. Here's a generalized outline of what a shutdown process might look like:

Scoping Phase

- Identify the need for a shutdown based on maintenance schedules, equipment condition, or operational requirements.

- Foundational planning for time frame, budget, and specific details regarding the assets.

Preparation Phase

- Establish a shutdown team comprising maintenance personnel, engineers, planners, and other relevant stakeholders.

- Develop a detailed shutdown plan outlining the scope of work, tasks to be performed, timeline, resource requirements, and safety considerations.

- Procure necessary materials, spare parts, equipment, and services required for the shutdown activities.

- Secure necessary permits, clearances, and approvals from regulatory agencies and internal departments.

- Conduct safety briefings and training sessions for personnel involved in the shutdown.

Execution Phase

- Carry out planned maintenance tasks, repairs, inspections, upgrades, and modifications according to the predefined schedule and sequence.

- Monitor progress, address any unforeseen issues or challenges, and adjust plans as necessary to ensure timely completion of work.

- Complete all scheduled maintenance activities and verify that all objectives of the shutdown plan have been achieved.

Start-Up Phase

- Perform tests, trials, and commissioning activities to verify the functionality, integrity, and safety of repaired or upgraded systems.

- Conduct performance tests to ensure that equipment meets specified requirements and performance standards

- Hand over the facility or equipment back to operations personnel for resumption of normal operations.

Review Phase

- Conduct a post-shutdown review to evaluate the effectiveness of the shutdown process, identify lessons learned, and make recommendations for improvement.

- Prepare a shutdown report summarizing key activities, outcomes, observations, and recommendations.

How do I schedule a plant shutdown or emergency turnaround

ParFab is a dedicated specialist in scheduled and emergency turnarounds. Our certified and highly trained team have over 200+ years of combined experience of a spectrum of essential disciplines, including total project management, execution estimating, planning and scheduling, cost controls, sub-contract management, materials management, and seamless logistics coordination.

Whether you need to schedule a shutdown, have an emergency turnaround, or have an alkylation shutdown project - our 24 hour call out team is ready.

Have questions? Contact us today.